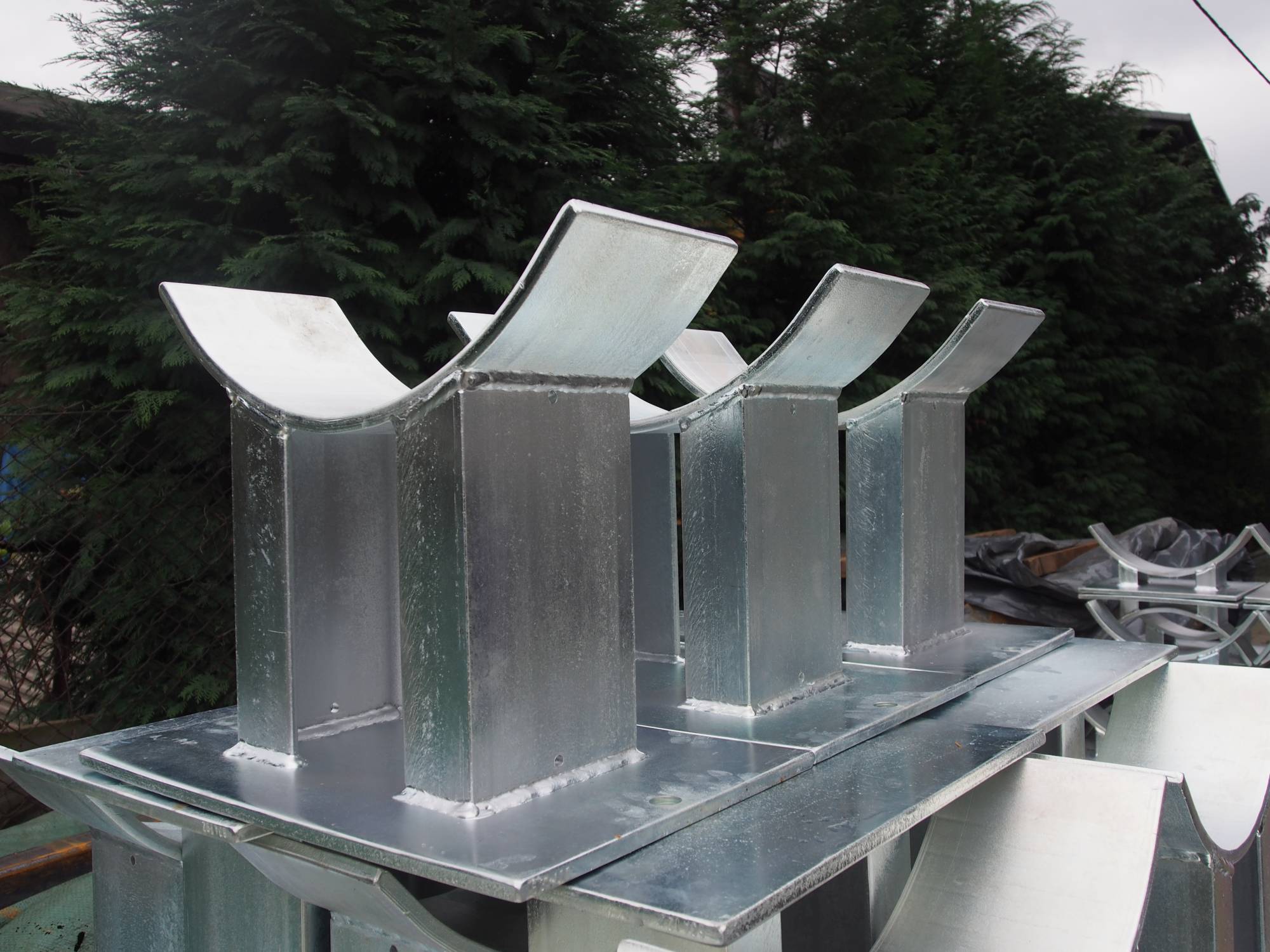

Pipe Supports for Piping Installation

Customer - SediCon AS

Scope of Work:

- Fabrication of Galvanized Pipe Supports – 760 items, over 30 tons of steel

- Delivery of fasteners

- Fabrication of shipment protective structures

- FAT testing

- Packing

- Shipment to Iran

- Creating of doc pack- MRB, FAT Procedure, Packing Procedure

- Project Management

The Stand for motor and pump

Customer - Norwegian company

Place of installation - Norway

Kraken’s scope of work:

- Design of the stand according to machine directive and customer requirements

- Fabrication doc pack

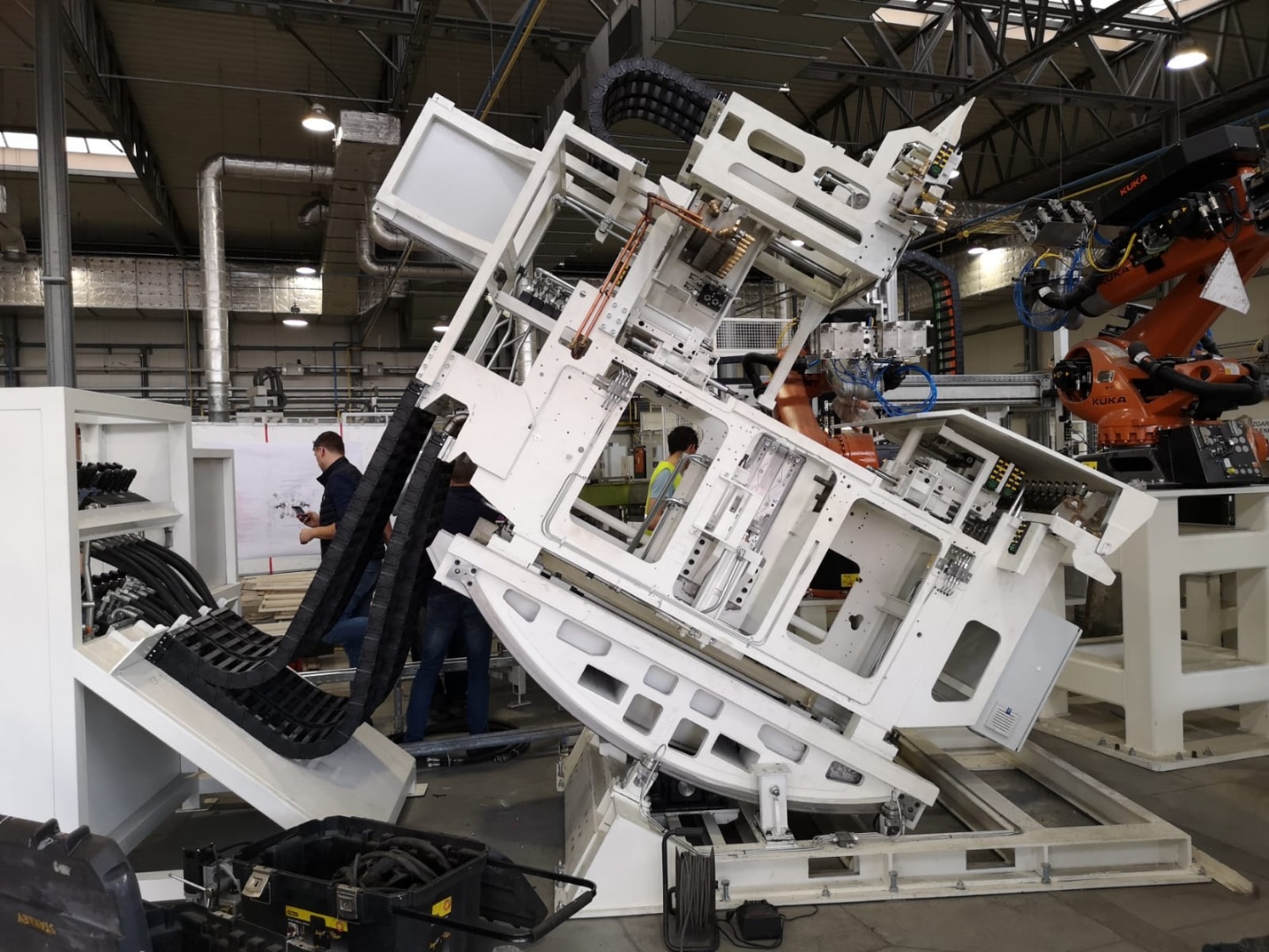

Redesign and refurbishment of Casting Machine

Customer - International company delivering casting parts for automotive sector

Kraken in cooperation with partners has delivered challenging project of redesign and refurbishment of Casting Machine.

The scope of delivery included:

- Redesign of all main components to meet new requirements

- Refurbishment of main structure

- Design of hydraulics system

- Design of water cooling system

- Design of lubrication system

- Assembly

- FAT

- Commissioning

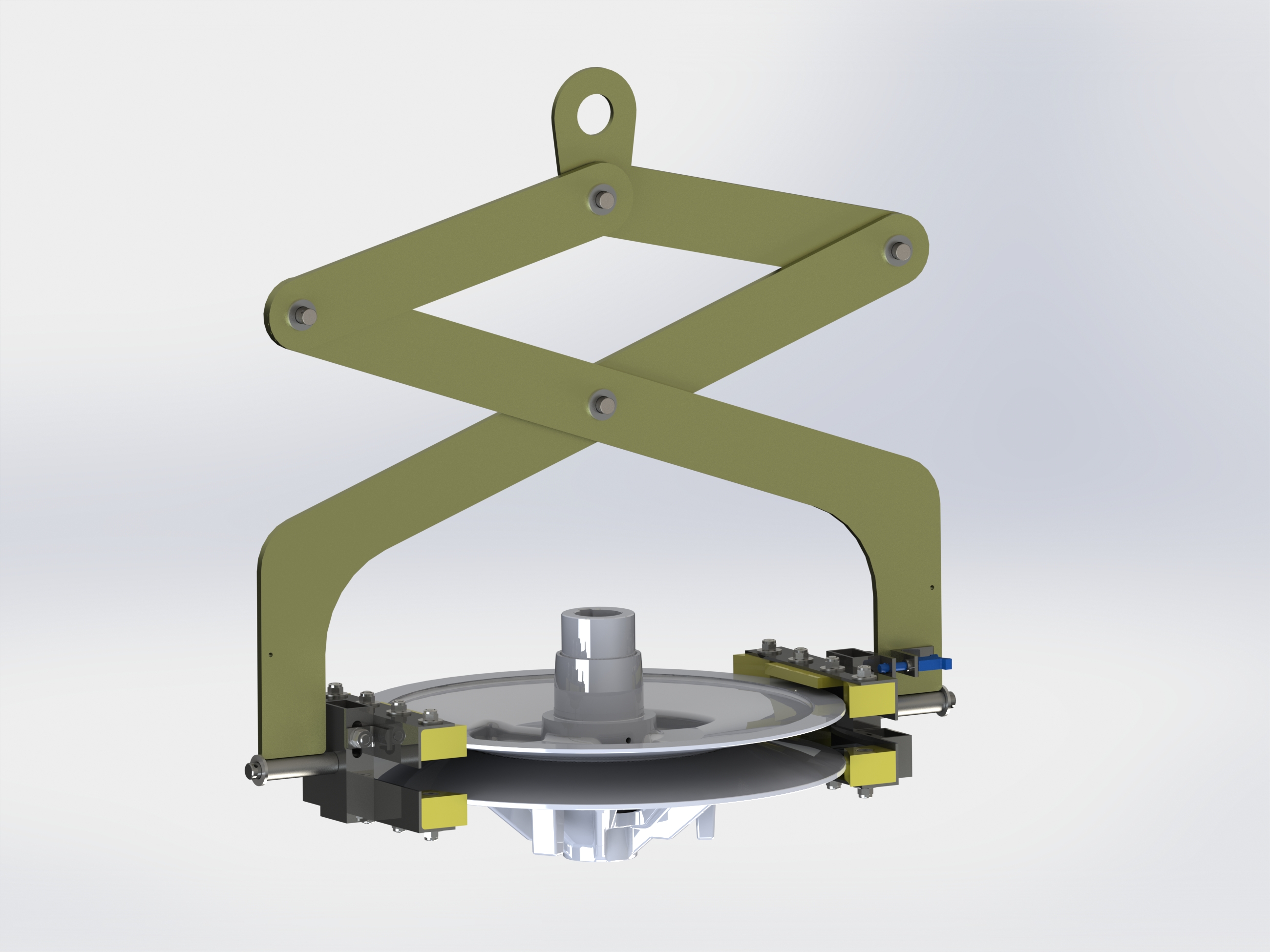

Design and fabrication of Pulley Blocks’ Clamp

Quite small, but very usefull during the assembly process of machines for the agricultural industry. It is capable of lifting blocks of pulleys in both vertical and horizontal positions.

The clamp uses the weight of the Pulley to create enough force to prevent Pulley from slipping.

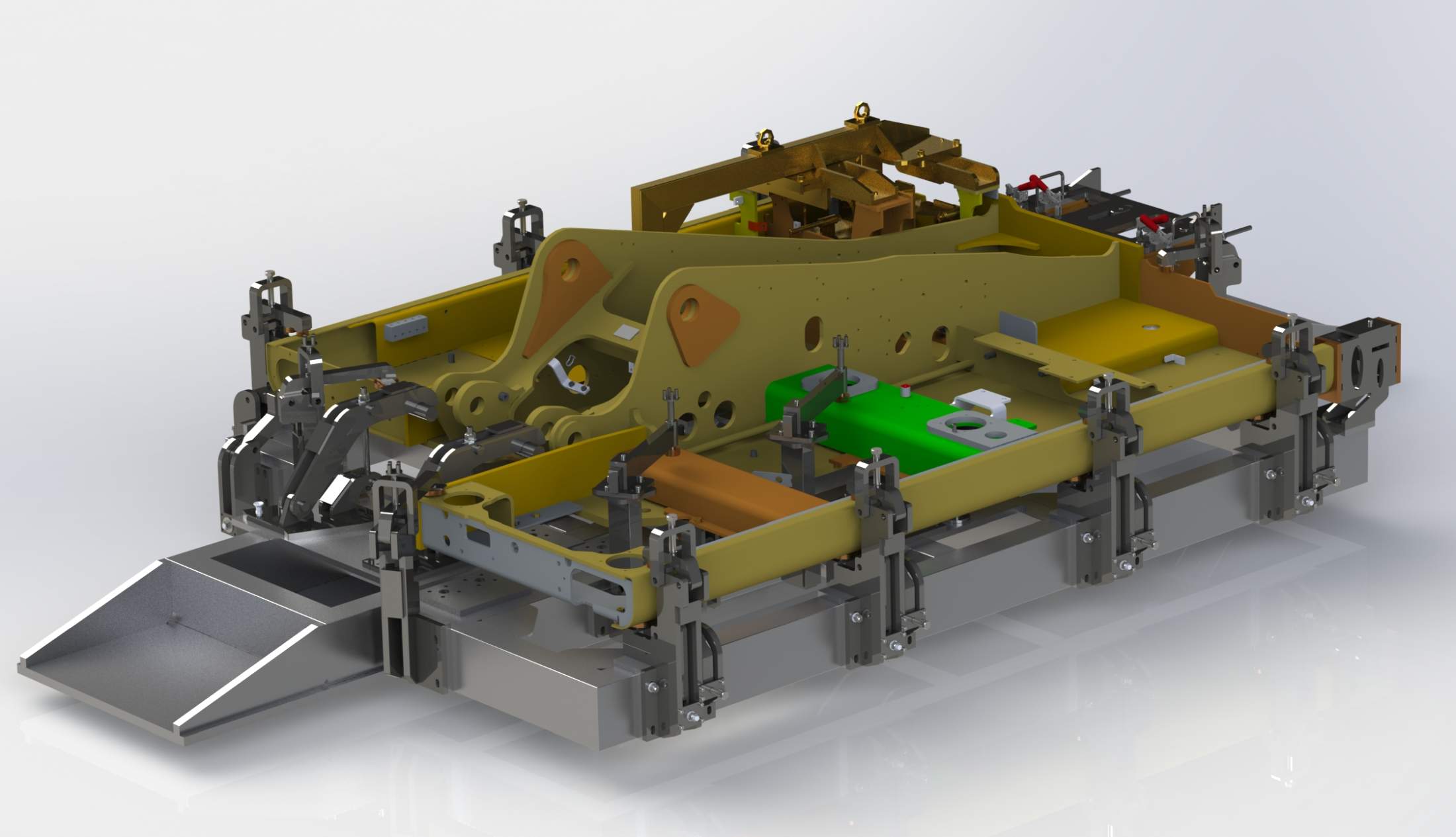

Design and Fabrication of Welding Jig

Kraken has been awarded a contract to design and fabricate Welding Jig for an international company – one of the key players on heavy machines market.

A jig is a large brace that keeps a welding project stable in the face of pressure, heat, motion, and force.

A quality jig will streamline welding work by keeping parts together in a vice grip. Whether the welding is entirely manual, partially automatic, or fully robotic,

a jig moves the workpiece while the tool remains stationary.

Every welding job involves a number of different tools. It is very common to use welding jigs on a project due to their strength and dependability.

Jigs make welding jobs easier, quicker, more accurate, more comfortable, and more cost-efficient.

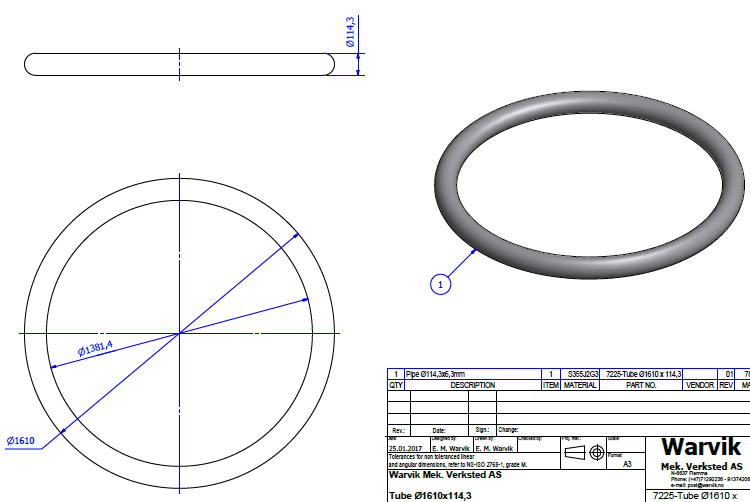

Rings precisely bended and welded

Customer - Warvik Mek. Verksted AS

Scope of Work:

- Fabrication of Rings, DIA 1610mm made of Tube DIA 114.3mm, 6.3mm, thick. Tolerances after bending and welding +/-2mm

- Packing

- Shipment to Norway

- Quality inspection certification

Design of Top Section of Soil Plug Removal Tool

Customer - Deep C Solutions AS

Place of installation - Beatrice Wind Farm

Scope of Work

- 3D design of Top Section of Soil Plug Removal Tool

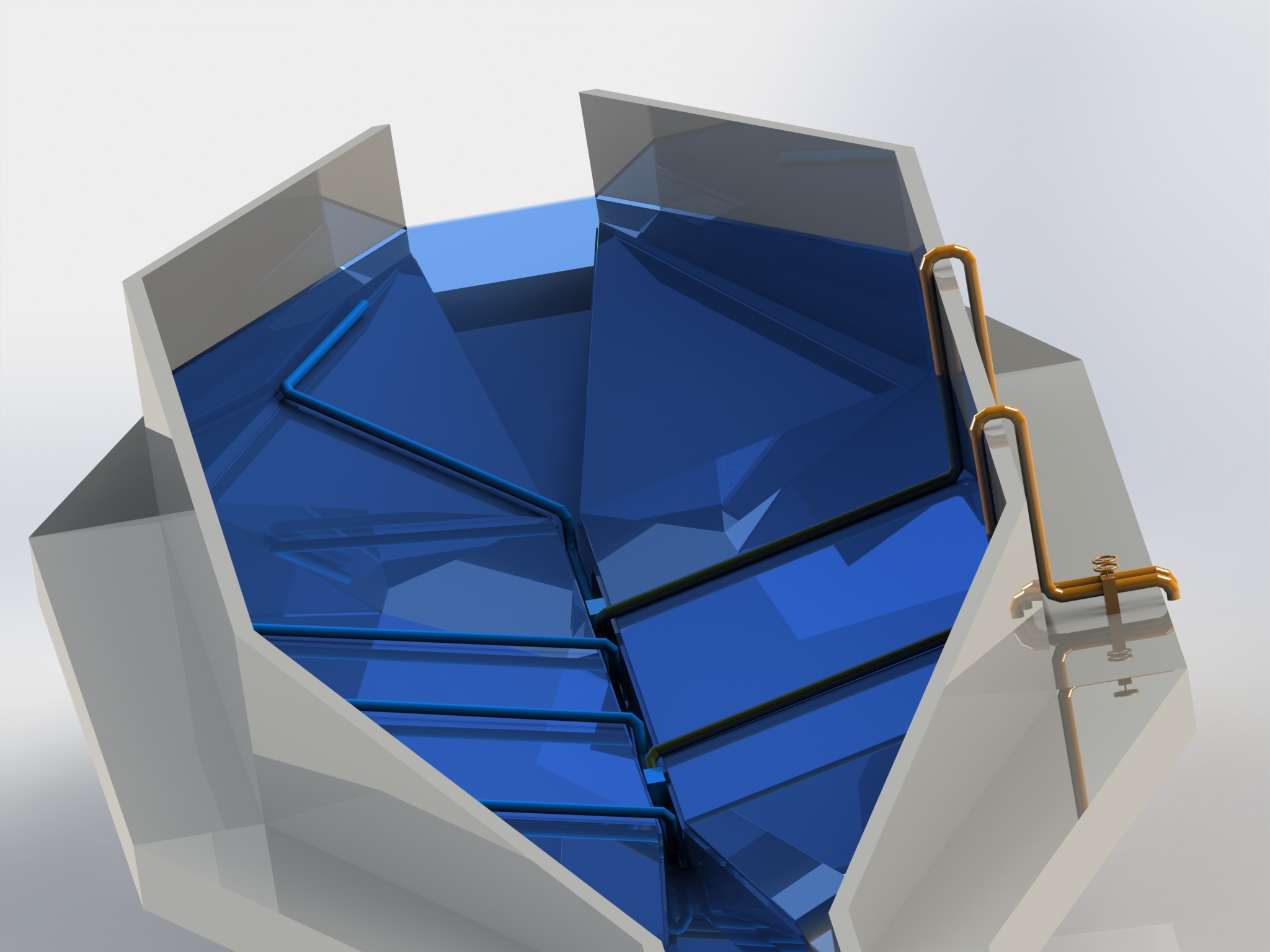

Piping Installation for SediCon Sluicer

Customer - SediCon AS

Place of installation - Nepal

Scope of Work:

- 3D design of Desander (tank)

- 3D design of Sluicer Installation

- 2D fabrication documentation